Katana has become a symbol for Japan. Also known as Samurai sword, it roots in a really long time ago and leaves a deep impression on lots of people. It's not easy to make a katana. Follow me to pay a visit to the Japan Katana Forging Research Institution below.

The signboard is a little small and the facade of Japan Katana Forging Research Institution is a little tattered. This is really disharmonious with the worldwide influence of katana, XD.

In Japan, katana makers are called as bladesmith, Seiken no Burakkusumisu or sword worker. While making a katana, a rather high-end technique is gathered. As a whole, after making the blade, quenching and polishing, bladesmith needs to make white wooden handle to keep the blade for sale. But the hilt, scabbard and Tan belong to another manufacturing line. They will be decorated by professional metal workers. In the Japanese history, sword workers have different factions. Some of them are even exclusive workers from shogunate.

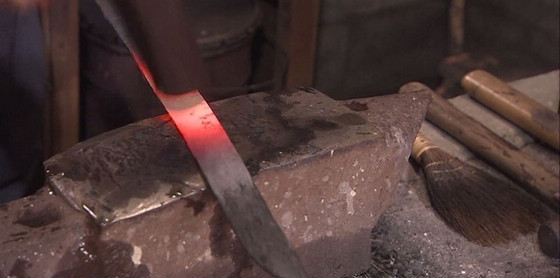

Go to factories of making swords, you will find all

katana are fully handmade. They are processed by experienced old workers personally. Lots of time is spent on making a katana. Workers have never stopped thinking about improving the making methods. Raw materials are high-class Tamahagane in Japan, which will only produce deluxe artworks.